Epoxy or Polyester is a debate that is always present in a surfcamp or in surf schools. And in general, among surfers it is always usual to discuss which of the two is the best option for our boards.

More and more brands produce their models with these types of resin to give the surfer the option to choose one as it suits him. But, do you know which is the best option? Here we clarify your doubts.

New materials in Surfing: Resin

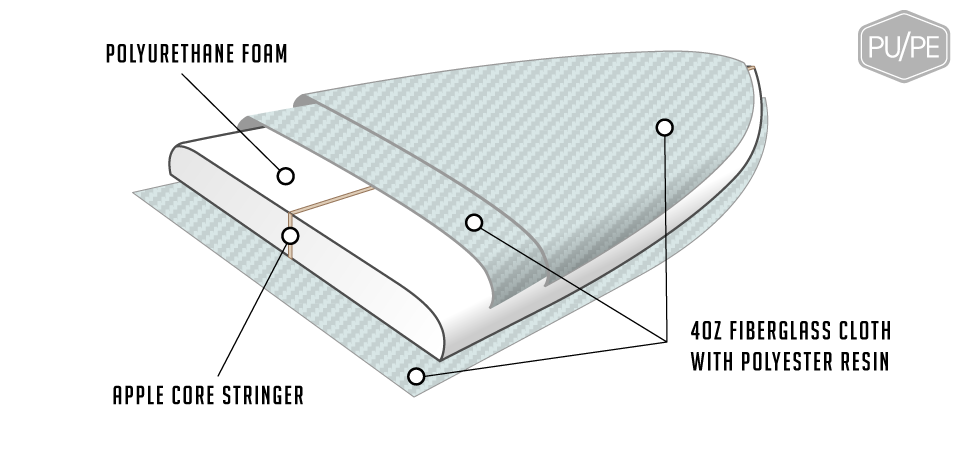

Conventional boards are manufactured with a polyurethane foam interior and a polyester resin exterior, a combination that has been on the market for approximately 50 years.

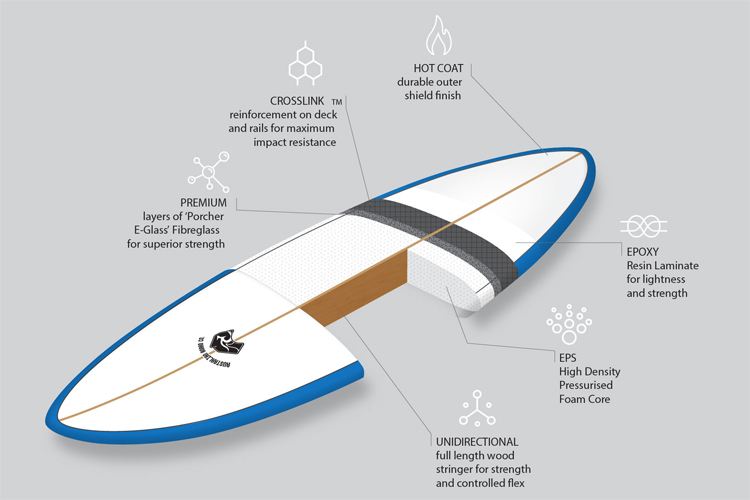

While Epoxy tables are manufactured with an interior of polystyrene foam and Epoxy resin, this being a combination of more modern materials and in constant development.

Epoxy Features Endurance:

One of the greatest advantages that Epoxy resin offers is that it is of greater hardness and resistance compared to polyester resin tables.

Every surfer knows how fragile polyester boards are and how quickly cracks appear on them.

This does not mean that Epoxy boards are indestructible, however, the hardness that Epoxy offers us guarantees greater resistance to shocks. Maintaining the good condition of the board for much longer.

Lightness:

Among Epoxy or polyester surfboards, Epoxy boards are lighter. This lightness is given by the inner polystyrene foam material, which is much less dense and therefore lighter than the traditional polyurethane used in polyester boards.

Less flexibility: Less response

Epoxy boards have greater resistance and buoyancy (Due to their lightness). Which is a major disadvantage in choppy (or rough sea) conditions, as it will absorb bumps and wave vibrations worse.

Many surfers who have used them also note that epoxy boards lack the flex and response of polyester boards. A mandatory flexibility for smooth maneuvering.

Epoxy Resin: More ecological

The materials used in epoxy boards release less harmful substances to the environment during their manufacturing process, compared to polyester.

Since the closure in 2005 of Clark Foam (The largest foam manufacturer), due to its inability to adapt to environmental policies, it was the push for new forms and materials to be used in the surfing industry.

Types of epoxy boards: EPS and PE

Expanded polystyrene (EPS): It is the material used in the cheapest epoxy boards. It is a very complex material to work with for shapers and of low resistance. Its biggest problem is that if the board breaks, it will absorb water like a sponge.

Extruded polystyrene (EP): It is an easier material to work with for shapers, its internal structure of closed cells will not absorb water in case of breakage of the board, being this material more resistant than EPS.

Epoxy or Polyester. Which is the best option?

This depends on many factors: The level of the surfer, the type of waves they are used to, if they are a beginner or advanced surfer, among others, so in summary:

We can say that Epoxy boards are perfect for small waves. (For its buoyancy and paddling quality).

While for medium to large waves, polyester boards are still the best alternative due to their flexibility and response in situations that demand fitness.

An important fact to take into account is the budget available, since Epoxy tables, especially the latest generation, are more expensive than conventional ones. But they are a good investment if used correctly.

So, have you decided to choose your board? If you have children, we hope this post will help you choose the best option for the children’s first surfboard and more when they will be starting either in a surfcamp or a surf school.